PIPETTE / DISPENSER / CUSTOM MADE & OEM

PIPETTE / DISPENSER / CUSTOM MADE & OEM

In Nichiryo’s micropipette models, there are seal ring type non-grease types that are grease-free. The high lubricity and airtightness of the seal ring enables smooth operation and high precision pipetting.

For micropipette models that require grease, it is necessary to periodically apply grease after autoclave (121° C, 20 minutes) sterilization. Non-grease micropipette types which do not require grease can be safely used without maintenance even after autoclave (121° C · 20 min.) sterilization.

The non-grease seal rings used by the Nichiryo Micropipettes are more durable than the general grease type models, so they will last and can be used with confidence. Out of the Nichipet Premium models, NPP - 2 - 200 use the durable seal ring, and it has approximately 600,000 times of pipetting durability.

Nichiryo’s seal rings are made of fluorocarbon resin, so they have excellent chemical resistance.

5-year warranty

Autoclavable

Micropipette

Standard Model

Autoclavable

Micropipette

Solvent Resistant

Autoclavable

Micropipette

Fixed Volume

Fixed Volume

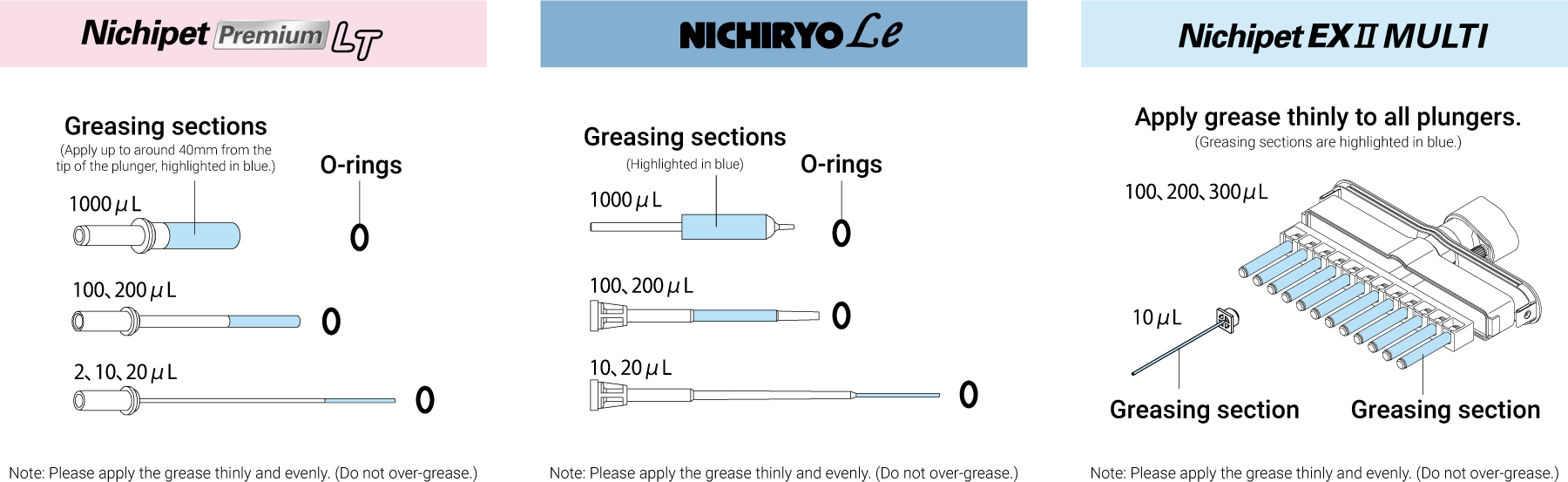

Stroke load reduction models Nichipet Premium LT and Nichipet EXⅡ MULTI use grease that is resistant to autoclave (121° C, 20 minutes) sterilization. There is no need to reapply grease every autoclave sterilization, be sure to use only the supplied grease when applying grease is needed.

Fatigue Free

Autoclavable

Micropipette

Autoclavable

Multi Channel Pipette

Fatigue Free

5-year warranty

Autoclavable

Micropipette

Autoclavable

Multi Channel Pipette

Light&Elgonomic

Model for Starts

Select a Region / Language

Asia-Pacific

Americas

Europe, Africa, Mid East